Tel: 0086-576-86016298

Fax: 0086-576-88041238

E-mail: admin@ddwmould.com

Add: No. 150, Yinshan Road, South District, Huangyan, Taizhou, Zhejiang, China

PET Preform Mould making process |

| Author: Date:4/18/2016 7:19:01 PM |

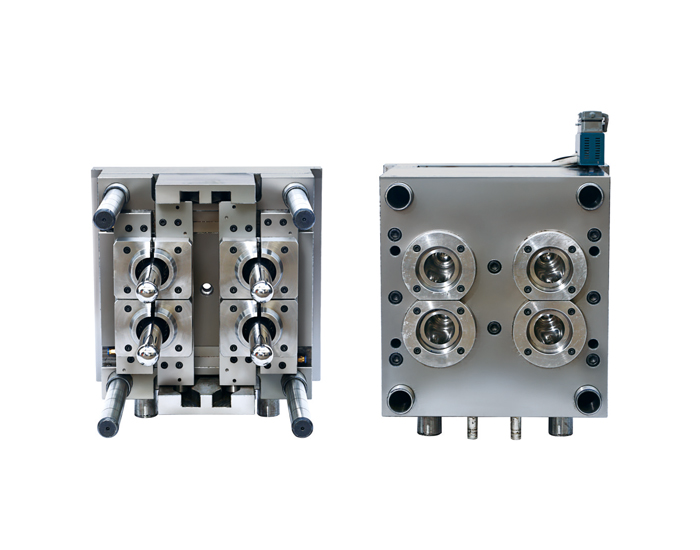

PET Preform Mould making process 1) ESI (Earlier: Supplier Evolvement ) : this stage is mainly discussion between customer and Supplier for product design and mold development technology, the main purpose is to let the Supplier clearly grasp the product’s design intent and precision requirement, but also for product designers to better understand the ability of the mold production, the process performance of the product, so as to make a more reasonable design of PET Preform mould. 2) Quotation, including the price of the PET Preform mould, the mould life, flow process, machine tonnage as well as the mould delivery date. (a formal detailed quotation should include product size, weight, mold information such as size, weight, steel, cavity, mold life, guarantee time.) 3) Order (Purchase Order) : customer ordered, arranged deposit, and suppliers accept s order. 4) Production Planning and Schedule Arrangement: in this stage, need give customer a final reply of delivery date of molds. 5) Design : Design software Pro/Engineer, UG, Solidworks, AutoCAD, CATIA, etc 6) Purchase materials 7) PET Preform Mould processing (Machining) : process generally content lathing, milling, heat treatment, grinding, CNC, EDM , cutting line , coordinates, JIG grinding, laser engraving, polishing, etc. 8) PET Preform Mold Assembly 9) PET Peform Mould test (Trial Run) 10) Sample evaluation report (SER)  |

Copyright (c) TAIZHOU DOUBLE WORLD PLASTIC&MOULD CO., LTD. All Rights Reserved