Tel: 0086-576-86016298

Fax: 0086-576-88041238

E-mail: admin@ddwmould.com

Add: No. 150, Yinshan Road, South District, Huangyan, Taizhou, Zhejiang, China

Three generation PET Preform mold development |

| Author:Melissa Date:9/25/2017 3:42:37 AM |

Nowadays technology develop so fast, mold strucutre change in big extent also. Take PET Preform Mold for example, the first generation oldest type is common preform mold with short tail or long tail. Mold photo is as following.

Mold for long tail preform as left sample in following photo, need cutting by hand, mold for short tail preform as middle sample, no need cutting.

This kind PET preform mold strucure is simple, Eccentricity is compared high, mold production needs worker who has rich experience to handle with. Mold life is around 500000 shots. Molded preforms don’t have very high quality, usually used for disposible bottle packing. Long tail mold need cutting by hand, so need much labor cost. Advantage is lowest mold charge

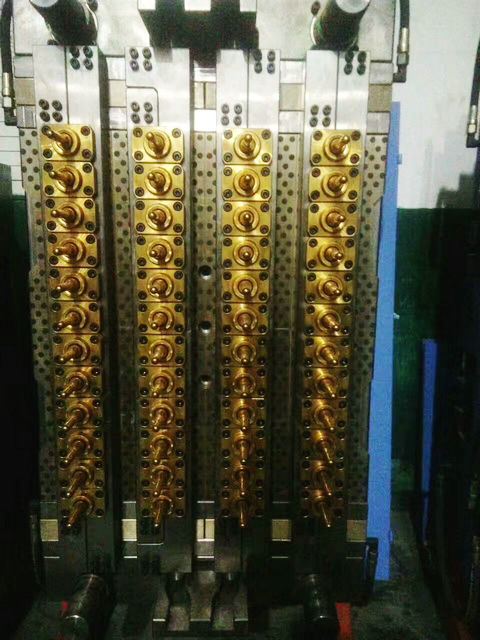

And the Second generation is self-locking common preform mold, this kind mold structure is compared complex, the following photo is for reference. Eccentricity is compared lower, injection production is easier to deal with. No need cutting, save labor cost. Mold life is around 800000 to 1 millon shots Mold charge is around double for common preform mold

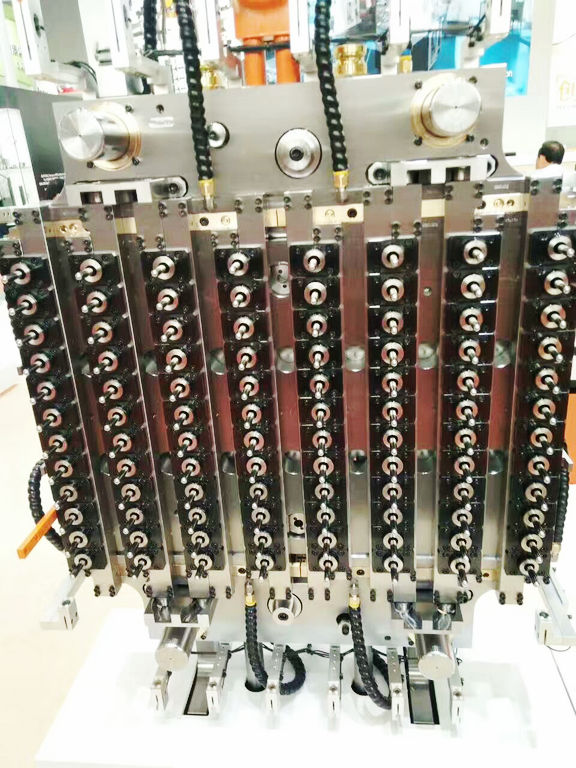

The Third generation is self-locking penumatic preform mold. Mold structure is as following photoes.

In this way, it is no doubt that the mould can be used for 2 million shots without any maintenance, meanwhile, the wall thickness difference between is not more than 0.10mm (length<=100mm), weight difference is less than 0.3g; turning center processes make sure that every mould parts can match very well to ensure mould concentricity; Proper distribution of cooling water system improve productivity effect and molding cycle only takes 15seconds. Utmost 144 cavities in one mould.

|

Copyright (c) TAIZHOU DOUBLE WORLD PLASTIC&MOULD CO., LTD. All Rights Reserved